CTC MACHINERY

THE BEST OF THE BEST

PHARMACEUTICAL & FOOD MACHINERY

เครื่องตอกเม็ดยา

ZPM series Rotary Tablet Press

ZPM series Rotary Tablet Press is a type of automatic rotary and continuously tableting machine, which is widely applicable pharmaceuticals, foodstuffs, chemicals and electronics industries to compact the granular materials into tablets. This machines is suitable for compacting granular materials with the content of fine powders not exceeding 10% into tablets. The machine can make round or irregular tablets with engravings on one or both sides of the tablet. This machine is also applicable to making tablets of Chinese traditional medicine.

Features :

1. The machine mainly consists of the machine proper and electrical control system.

2. The machine adopts a framework and roller mechanism with high strength and high rigidity. The main compression is 60kN and the diameter of the main compression roller is 200mm, to ensure the tableting quality.

3. The working area adopts the fully enclosed structure with transparent windows, to prevent the powders from flying everywhere. The parts to be in contact with the pharmaceuticals are made of stainless steel or specially treated in the surface. The tableting compartment is completely separated from the transmission, effectively preventing the cross contamination and in compliance with GMP standard. The windows are supported by means of air spring door holders, easy to open, for the convenience of rapid assembly and dissembly of the parts in the tableting compartment and cleaning and maintenance.

4. The inverter is adopted for the adjustment of speed for the continuous adjustment of the speed of the turret, with the rotary speed of the turret to be displayed in the operating panel.

5.The machine is provided with Main compression overload alarm, Emergency stop alarm and Defective inverter alarm.,etc.

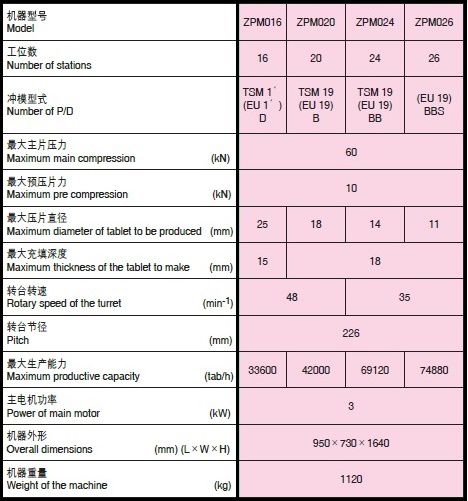

Technical Parameter